The Footprint Company started over 9 years ago with a simple mission: to support and enable net zero design innovation in the building industry. Along with many of our clients we are so familiar with terms like, net zero, embodied carbon, and greenhouse gases that we can sometimes presume they are common knowledge. Yet, it can be helpful at times to go back to basics, to help newcomers to this mission come to terms with what can be a complicated and intimidating subject matter for the uninitiated. Here’s our “101” version on embodied carbon that we hope you find helpful, perhaps to send on to less enlightened colleagues and friends in the industry.

Embodied Carbon, the definition

Embodied Carbon is the emissions footprint that comes from extracting, transporting and manufacturing building materials. Each and every stage of getting building materials to a construction site and into the actual development, causes greenhouse emissions (greenhouse gasses or GHG).

The emissions as a result of materials are….material

We have a reasonable and intuitive understanding of the operating impact that buildings can have on greenhouse emissions yet many don’t stop to think of the impact f simply creating these buildings in the first place. Embodied carbon accounts for 25%1 of building sector emissions and up to 11% of all “human caused” emissions globally. It is material and a significant contributor to the greenhouse gas problem.

Now is the time to take action

The 2030 Challenge is an initiative by Edward Mazria and Architecture 2030 to make all new buildings and renovations carbon-neutral by the year 2030 to avoid the catastrophic effects of climate change caused by the building sector. To achieve this, the embodied carbon emissions from all new buildings, infrastructure, and associated materials must be reduced by 65% by 2030, and zero by 2040. 2030 is less than 9 years away and in the cycle of planning and developing major and even lesser construction projects that is literally the equivalent of the blink of an eye.

Understanding the embodied carbon in materials is critical to solving the problem.

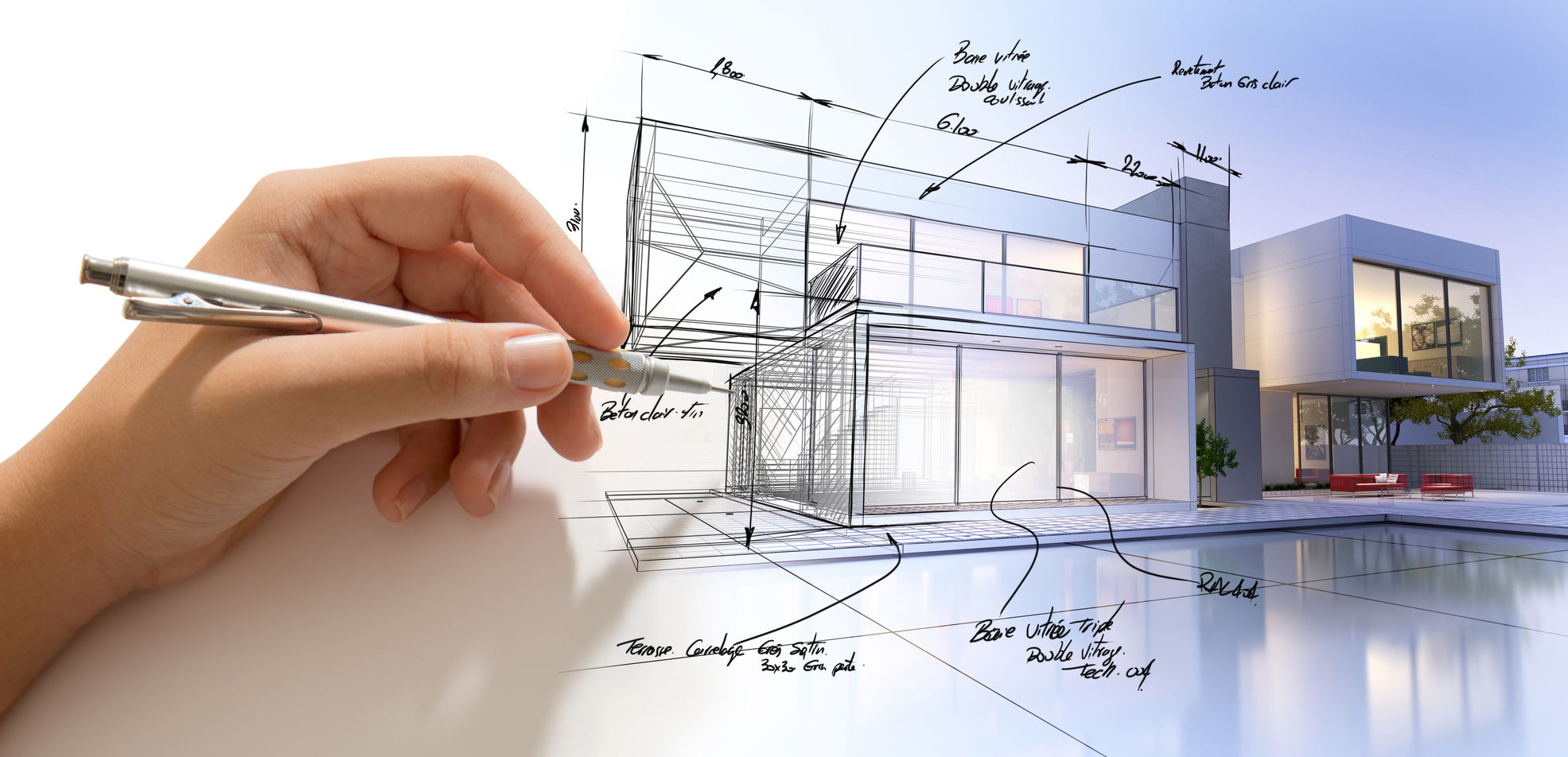

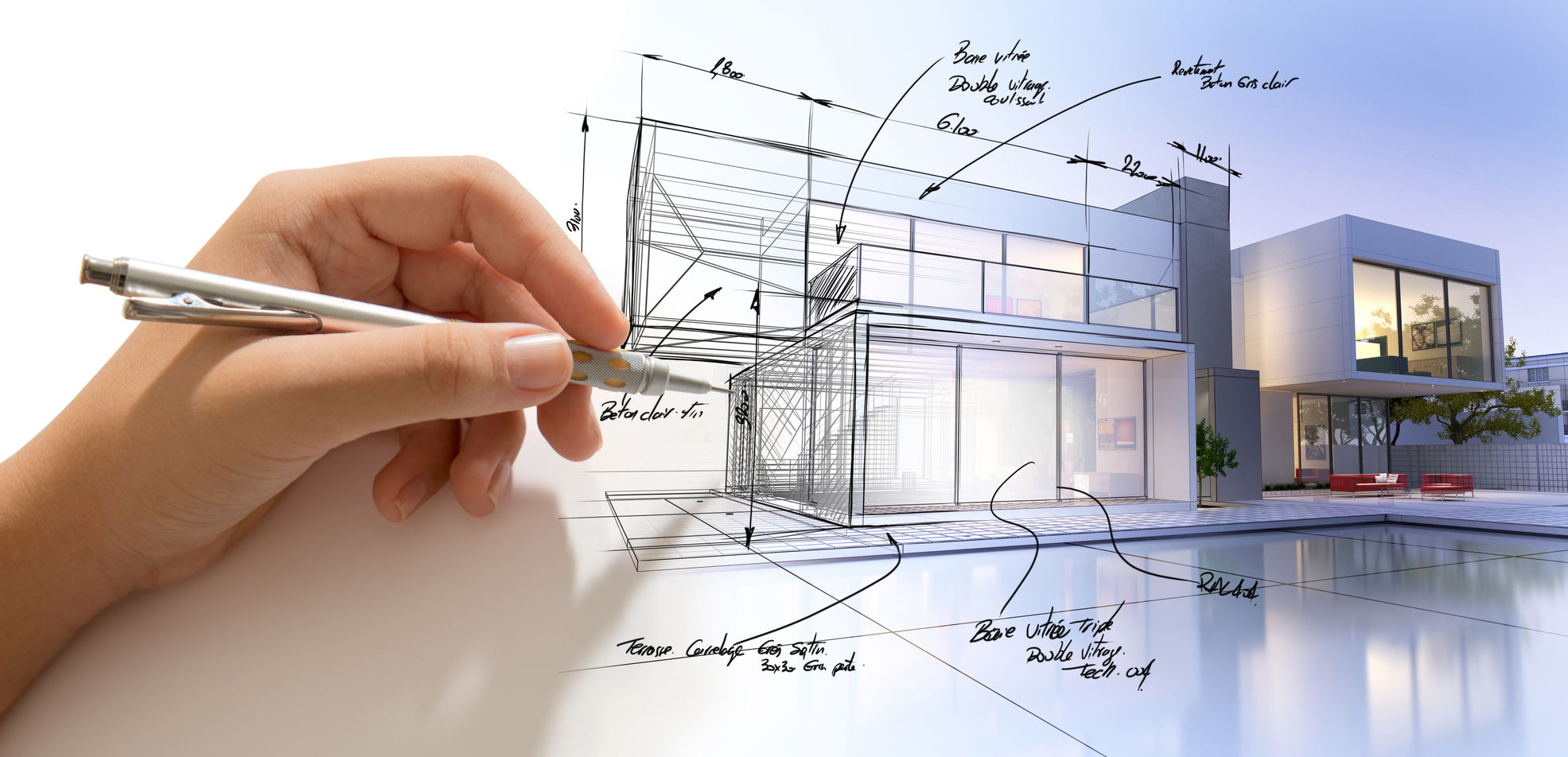

Understanding the embodied carbon associated with each material in a project, and thus the embodied carbon footprint associated with the project as a whole is the only way we will ultimately be able to start the process of reducing a project’s impact.

This is currently achieved through a life cycle assessment (LCA) where all phases of a material’s lifespan (extraction, manufacture, transportation, use and disposal) are considered, calculated for a range of environmental impacts. This will normally include CO2-e emissions (Global Warming Potential, or GWP).The total sum of these carbon dioxode emissions is the embodied carbon value assigned to one unit of that material. We can use LCA data to calculate the total “cradle to gate” or “upfront” embodied carbon impact of materials. This is crucial to enable us to sum all of these up to arrive at a calculation for the carbon emissions impact of the project as a whole.

In years past, accessing all the LCA’s for all of the materials under consideration for a project had been a difficult undertaking. Nowadays though, Environmental Product Disclosures are available from manufacturersThese assessments meet a set of international rules and are usually undertaken by independent parties to verify and publish the LCA’s of the relevant material. Other handy sources of data include LCI databases such as EPiC, from the University of Melbourne.

Technology has been developed to assist design decisions

There are literally thousands of materials available to designers of buildings and each decision made at the design stage will ultimately impact a project’s carbon footprint. Platforms like our own, The GreenBook, collate, maintain and provide guided access to the embodied carbon data for building materials across the globe. Through our platform, designers can access data on 2500+ rates for materials and complex assemblies, all of which is updated twice a year, saving hours of research. These are integrated to visual design guides and performance benchmarks, making it easier for architects and planners to envision and optimise their options. Our whole mission is to make it easier for designers to make better, more informed decisions, at the point of design.

Clearly all of the above is just the tip of the iceberg, yet we hope it lays out some of the key elements of the embodied carbon discussion. If you’d like to take the next step in understanding, our CPD courses are a great way to enhance your understanding. The one hour module, Materials Carbon Footprint and Low Carbon Design can be done in your own time and is available by on-demand video so very convenient.

Beyond that, this is our passion and we’d welcome the opportunity to talk to you further if you have any questions at all so contact us at info@footprintcompany.com.au.

If you would like to increase your knowledge or the knowledge of your team in a more practical way, we have just launched the second of our online CPD courses, the Net Zero Carbon Masterclass and you can enrol HERE.

Or if you’re ready to take on the challenge of embodied carbon, and take your projects to ‘Net Zero’ check out our new “roadmap” here.

1UN environmental global status report 2017