Roadmap

Embodied Carbon: What is it, and why does it matter?

Let us introduce you.

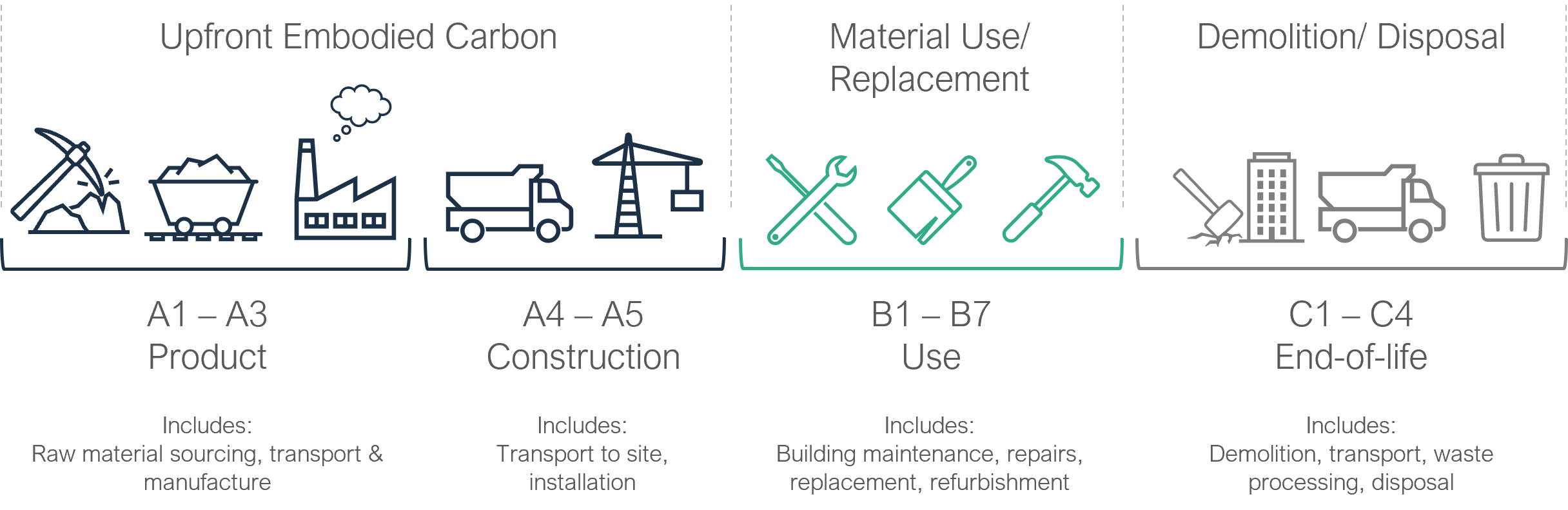

What actually is 'embodied carbon'?

The term ’embodied carbon’ refers to the Greenhouse Gas (GHG) emissions arising from the production and manufacture of materials and products.

This includes all emissions associated with the equipment that makes the materials, intermediate transport, and all other business operations to bring a product to market and installation in the building.

Generally, it can be described as ‘upfront carbon’ (Stages A1-A5), ‘use/ replacement’ (Stage B) and ‘end-of-life’ (Stage C).

The key standards for embodied carbon accounting are: ISO14044, ISO14067, and ISO21930.

Right: General Embodied Carbon stages across the building life.

Global Fossil Fuel GHG Emissions

Why does Embodied Carbon matter?

Globally, Embodied Carbon of materials accounts for ~50% of all annual human-made GHG emissions from fossil fuels.

Global consensus agrees on the need for an immediate 40% reduction in embodied carbon today, moving towards 65% by 2030, and net zero by 2040. Below are some examples from key industry bodies:

EMBODIED CARBON TARGETS

World Green Building Council: -40% from average practice by 2030, Net Zero by 2050

Royal British Institute of Architects (RIBA) & London Energy Transformation Initiative (LETI): -40% immediately, -55% by 2025, -70% by 2030, Net Zero by 2040

American Institute of Architects (AIA): -40% immediately, -45% by 2025, -65% by 2030, Net Zero by 2040

Green Building Council of Australia (GBCA): Net Zero by 2030

Low Carbon Living CRC: Start Best Practice Method of Measurement & Report immediately, Mandatory Quotas by 2025, -70% by 2030, Net Zero by 2040

Left: GHG Emissions by end-use. Adapted from Architecture 2030, 2018.

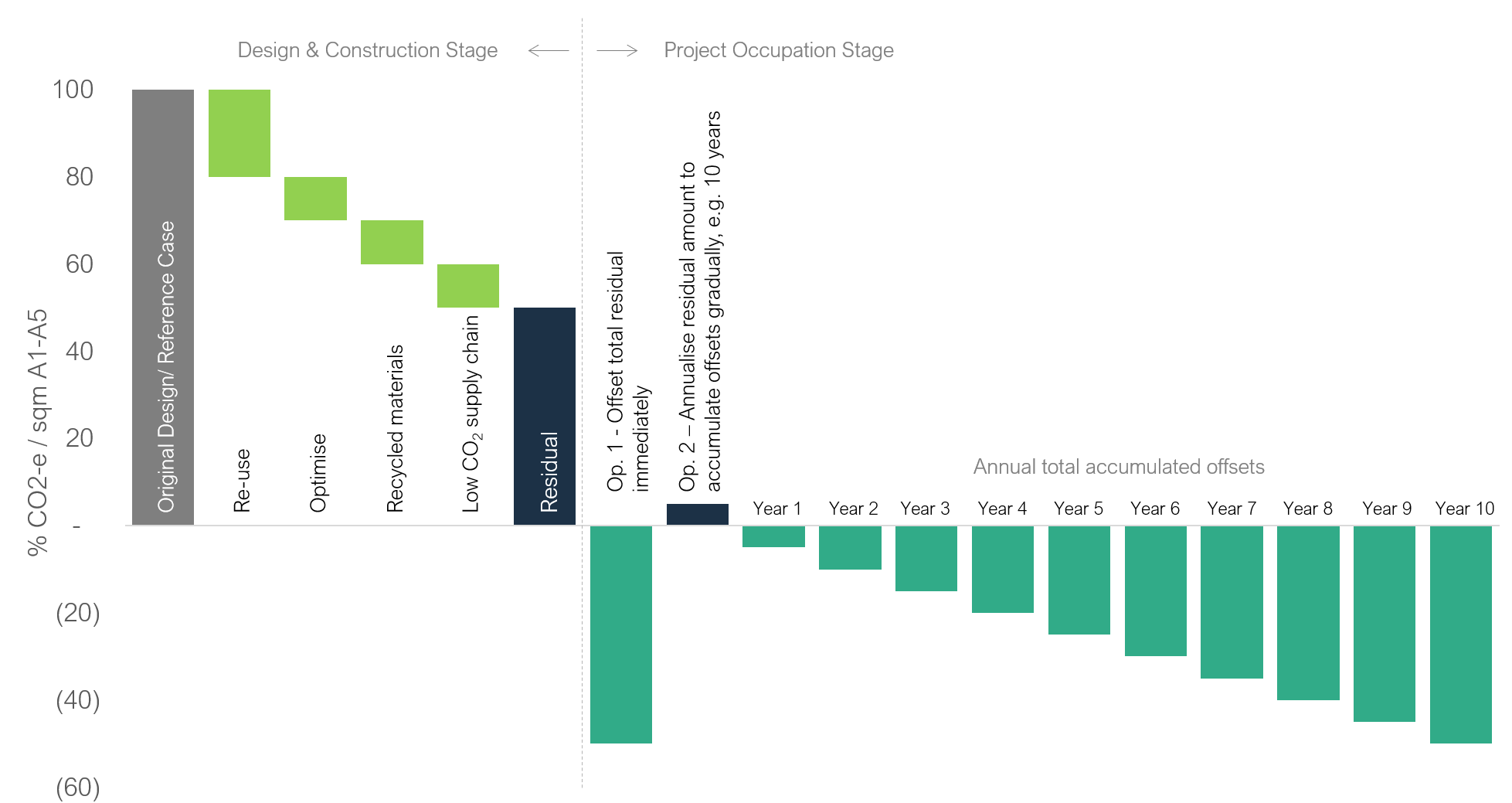

What is 'net zero' and 'carbon neutral'?

Due to current supply chain practices, it isn’t possible to make a building without an upfront embodied carbon impact. In order to balance to ‘zero’, we need to use offsets.

Net Zero Carbon and Carbon Neutral both describe design and construction approaches in which a project’s carbon emissions have been reduced as far as possible, and the remaining amount is ‘offset’ using an equivalent-sized carbon-positive investment of some kind, to bring the total carbon to zero. These offsets can occur either on-site or off-site.

The example on the right illustrates two methods of accumulating enough carbon-negative offsets to balance the remaining embodied carbon total.

The first steps during design and construction, in which circular economy principles are applied to ‘chase out’ embodied carbon, are typically cost neutral.

Using this methodology to fully offset a project with a 40% reduction in average embodied carbon would cost around AUD$20-30/ sqm for a single residential home to almost AUD$100/sqm for an A-grade office.

Contact us for assistance with feasibility and planning for offsetting embodied carbon in your projects.

Right: Achieving net zero Embodied Carbon using circular economy principles and gradual offsets over a selected building life span.

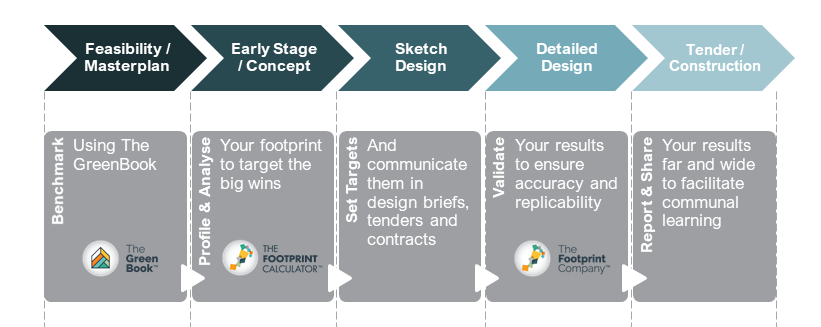

Delivering net zero

Here is The Footprint Company’s five-step guide to designing for Net Zero Embodied Carbon:

- Benchmark your project. Understand the size of the embodied carbon footprint of an average project of the same type sits in terms of average performance, and set a target for reduction. Use The GreenBook to find the right benchmark for your project.

- Break down or ‘profile’ the carbon footprint to target the big wins. Splitting up the data into the main building elements (e.g. structure, services, internal elements) enables designers to quickly understand where to focus attention to maximise embodied carbon reductions. Your can quickly do this using The Footprint Calculator.

- Set and communicate a Net Zero embodied carbon project budget/target. Setting performance targets in briefs and specifications is a powerful way to keep project teams focused and ensure results.

- Validate your results. Get in touch with us to Peer Review your Footprint Calculator results and ensure replicability, integrity and accuracy.

- Share, report & learn. Share results far and wide, to help facilitate communal learning and growth within the industry.

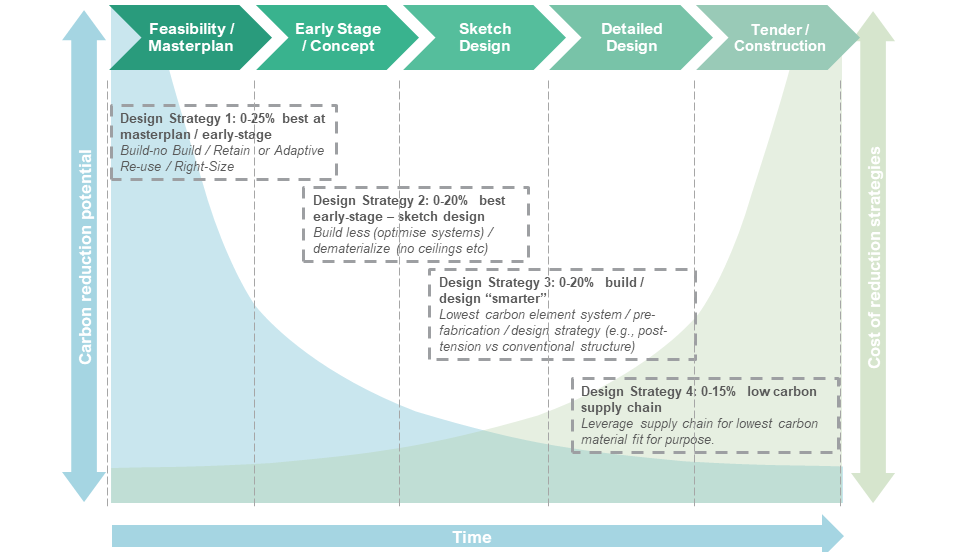

Left: Embodied Carbon design strategy hierarchy overlaid with typical design/ construction phases.

Net zero design strategies

Circular economy principles are key components of low embodied carbon designs. Here are a few design strategies to reduce embodied carbon in your projects:

- Determine scope for build/ no build. By re-using existing structures, scaling down the building size, and being economical with room sizes. This can contribute between 10 and 50% reduction.

- Build Right. Use the right design solution for the design challenge. Think about efficient material use and consider the best use of the material’s physical properties. This can have around 10% reduction impact.

- Build Smart. Reduce the burden on natural systems for raw material extraction and processing by using recycled materials, and use low- or no-carbon materials as far as possible. This can have a reduction impact of ~10-15%.

- Supply chain impacts. Consider the supply chain impacts of the materials used, for example manufacturing in different regions due to energy grid mixes. This can have an impact of around 10%.

Right: Embodied Carbon design strategy hierarchy overlaid with time and cost implications across the typical design phases.